Automation

State-of-the-art technology contributes to a lower cost, more efficient production, and a higher quality product. To achieve this value for the customer, Metcam has made significant investments in technology. Our newest investment is in Amada FabriVISION, which is a marvel of technology in the fabrication workspace. FabriVISION allows us to precisely and rapidly inspect a component or entire product for defects.

Quality inspection time is reduced from hours to less than two minutes. In addition, the system can be utilized to reverse engineer a product, significantly speeding up the prototyping process.

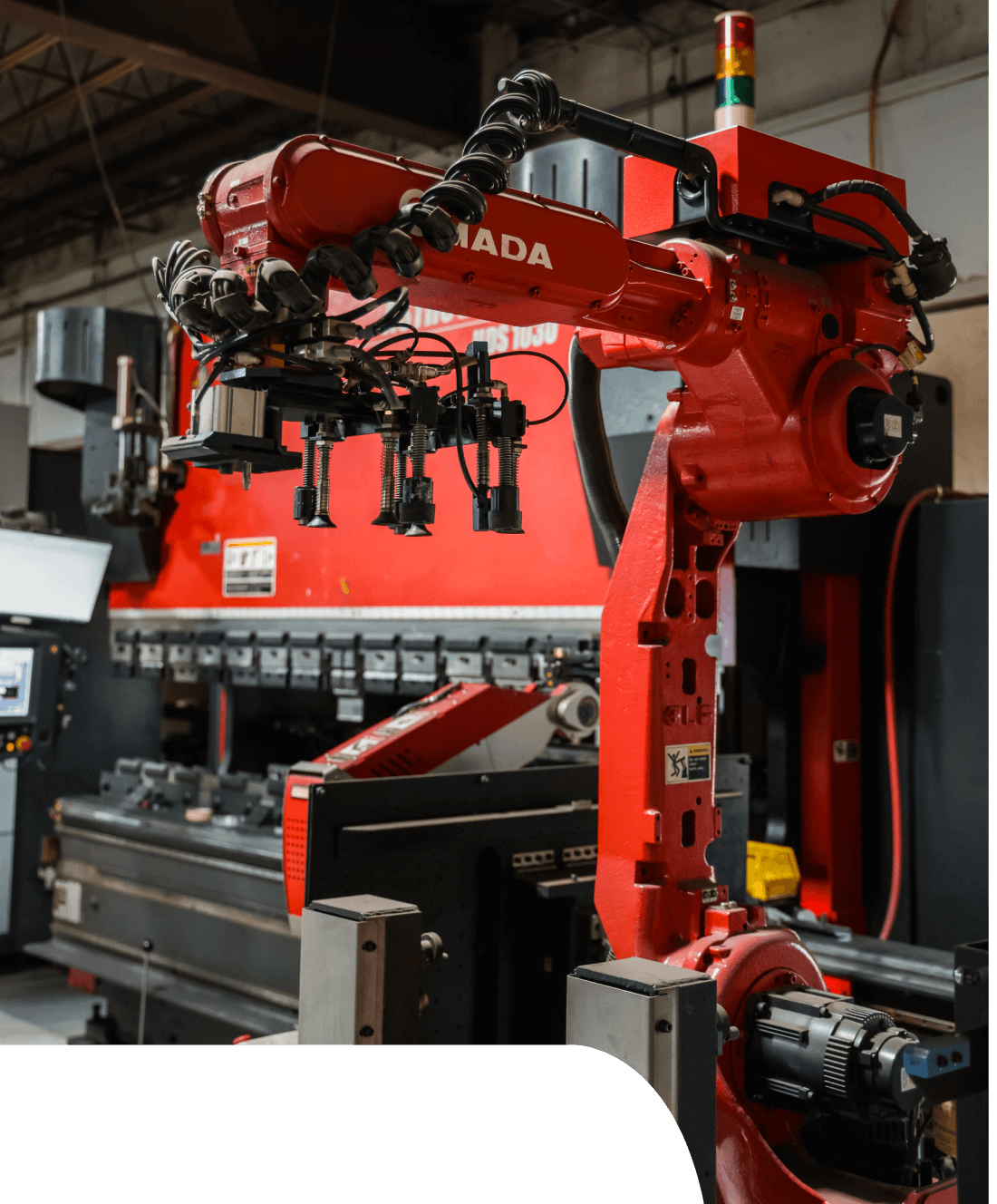

Metcam’s investment in automated equipment also delivers impressive efficiency improvements and reduced costs throughout the production process. Amada laser cutters with automatic tower feeders operate around the clock with minimal operator supervision. Amada automatic tool change presses cut setup and tool change times from hours to minutes. Robotic panel benders from Prima and Amada drastically cut setup time and operator supervision.

When making these investments, Metcam strives to utilize domestic suppliers. The strategy helps to strengthen U.S. manufacturing partnerships while also reducing service and parts procurement downtime.

Together, all of these automation advances make Metcam a leader in production efficiency, with less equipment downtime, reduced waste, and fewer defects. It all adds up to a lower-cost product, delivered faster.

Our current equipment line up includes:

Upcoming additions include:

QUALITY POLICY

QUALITY POLICY ENVIRONMENTAL POLICY

ENVIRONMENTAL POLICY