Vertical Integration

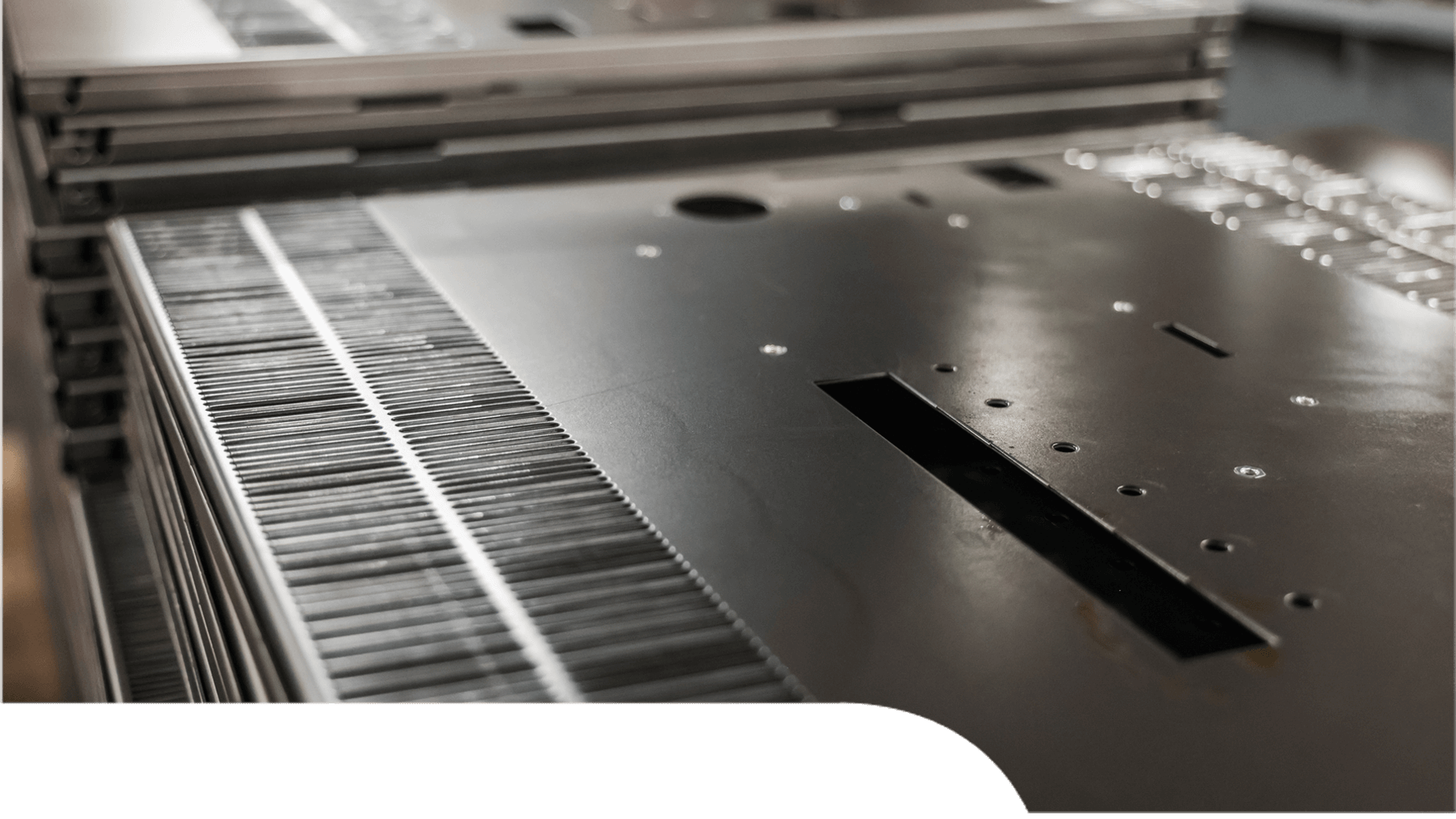

Metcam is committed to offering partners the increased quality,

reduced costs, strengthened supply chains, and shorter lead times

that can be achieved through vertical integration.

By leveraging Metcam’s expertise, you gain better control over all aspects of the manufacturing process, from material sourcing to product delivery.

Material scientists and engineers at Metcam are always available to collaborate with you to meet even the most challenging product requirements. Industry-leading technology allows Metcam professionals to streamline the production process beginning with the initial product design.

Having prototyping, materials sourcing, manufacturing, and

assembly under one roof means we can create the most effective process, reducing both cost and time-to-market.

Vertical integration also means that Metcam can ensure that your product reaches the market with the highest quality possible. Advanced prototyping and automated inspection capabilities both reduce testing times and ensure that quality expectations are met. Our team is geared towards delivering a quality final product, not just completing a manufacturing phase.

By eliminating the inevitable delays involved with shipping components between manufacturing phases, Metcam is able to achieve impressive reductions in production time. Design changes are also much less complicated when all phases of production are tightly integrated.

Perhaps the biggest benefit of vertical integration is having one contact for project management and production updates.

You no longer need to manage multiple smaller suppliers or be subject to competing priorities.

QUALITY POLICY

QUALITY POLICY ENVIRONMENTAL POLICY

ENVIRONMENTAL POLICY